3D printing placement - Purpose AM Systems

What was needed:

automated high-bay warehouse for small parts

Requirements:

very space-saving solution that loads and unloads the 3D printer in a small installation space.

Material:

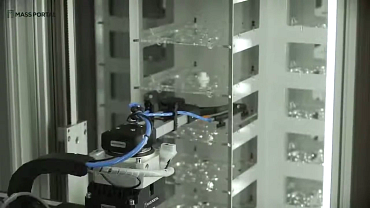

igus room linear robot in combination with a rotary gripping axis

Industry:

3D printing industry

Success for the customer:

lubrication-free construction that can be individually adapted to the available work area.

automated high-bay warehouse for small parts

Requirements:

very space-saving solution that loads and unloads the 3D printer in a small installation space.

Material:

igus room linear robot in combination with a rotary gripping axis

Industry:

3D printing industry

Success for the customer:

lubrication-free construction that can be individually adapted to the available work area.

Go to application

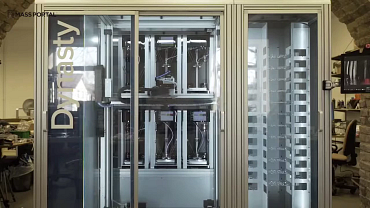

Mass production with 3D printers enables entire industries to produce individual components cost-effectively. Automated processes are needed to meet the high demand for manufactured parts. In this special case, the loading and unloading of the 3D printer. Empty glass plates are fed. After the printing process has been completed, the room linear robot removes the glass plate and stows it safely in a high-bay warehouse for small parts.The problem

In order to ensure a smooth process, manual intervention during loading and unloading is dispensed with in this special case. Among other things, because it cannot be ensured that the component has already hardened at the time of completion of the print. In addition, the combination of a room linear robot and high-bay warehouse allows round-the-clock operation.The solution

The solution for these requirements was implemented by means of an igus room linear robot. An individual solution suitable for the available installation space was developed as a link between the 3D printers and the high-bay warehouses. An uninterrupted production process can only be achieved thanks to the lubrication-free and maintenance-free components.The linear robot configurator

Discover our online configurator

With our intuitive online configurators you can create your own linear robot with just a few clicks. Fast, individual and with a fixed price.Discover the unlimited freedom with our tools now.

Go to the configurator

Low Cost Automation shop

Cost-effective robotics for your automation project

You can find the right robot for your individual application in our online shop.Browse, get information and order easily.

To the shop