Logistics robot final assembly - igus

What was needed:

cost-effective robot unit including gripper

Requirements:

maintenance-free, cost-effective, flexible, modular and easy to program

Material:

igus room linear robot, suction pads

Industry:

logistics/production

Success for the customer:

quickly integrated fully automated solution for end palletising processes

cost-effective robot unit including gripper

Requirements:

maintenance-free, cost-effective, flexible, modular and easy to program

Material:

igus room linear robot, suction pads

Industry:

logistics/production

Success for the customer:

quickly integrated fully automated solution for end palletising processes

Go to application

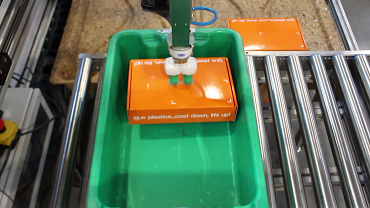

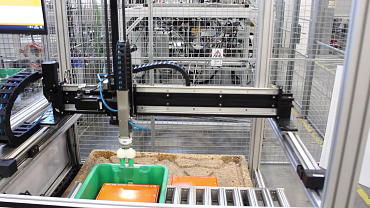

The system uses pick & place tasks to load goods into a rotary stacking container on a roller conveyor belt. A classic application in the field of logistics, where goods have to be transported and/or stored.The problem

The monotonous activity of loading packaged goods calls for a high manual effort. In order to increase production capacities and relieve employees, this process can be supported with simple and cost-effective automation solutions.The solution

An igus room linear robot in connection with a vacuum suction pad. This enables the loading of packaged goods of different sizes and weights. The simple and cost-effective integration into existing production processes can be implemented without any problems.The linear robot configurator

Discover our online configurator

With our intuitive online configurators you can create your own linear robot with just a few clicks. Fast, individual and with a fixed price.Discover the unlimited freedom with our tools now.

Go to the configurator

Low Cost Automation shop

Cost-effective robotics for your automation project

You can find the right robot for your individual application in our online shop.Browse, get information and order easily.

To the shop