Production of wooden pallets with lubrication-free linear bearings

Aloysius Krenzer KG manufactures Europool pallets and customer-specific wooden pallets with a high degree of automation. When the technology experts in the company order new systems, they contribute their real-life expertise - and also influence the system manufacturer to use drylin linear guides for certain applications. The reason is that dry-running bearings prove their worth in linear drives that operate highly dynamically under heavy loads.

Profile

- What was needed: linear guides in the drive and handling units of the pallet production systems

- Requirements: resistance to chips, dust, moisture and resin, dynamic movements, vibrations and alternating loads

- Industry: wood-working industry

- Success for the customer: compared to conventional ball bearings and recirculating ball bearing guides, Krenzer achieves significantly longer service lives with dry-running drylin linear guides. In combination with hardened steel shafts, the pillow blocks work precisely and maintenance-free even under unfavourable environmental conditions.

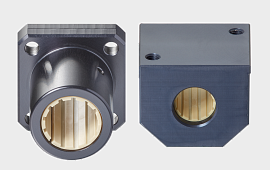

Ideal igus® component and sample option

drylin® pillow blocks

Completely lubrication-free with identical dimensions to recirculating ball bearing systemsFind out more

Free sample

Order your drylin® R round-shaft sample and convince yourself of the qualityOrder a sample now

Problem

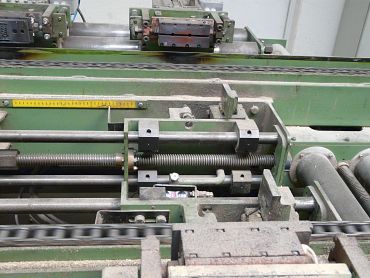

Components in pallet production systems are exposed to special loads. These include wood chips and dust, moisture and resin. In addition, the dynamics of many drives are high, with 50,000 strokes per day. This applies, for example, to the handling units of the nailing station. The linear guides must be able to withstand alternating loads in a dusty environment as the moving ends attached to the axes move up and down when they remove a board from the storage. Added to this are the continuous vibrations caused by nailing.The designers were dissatisfied with conventional bearings, such as ball bearings and recirculating ball bearing guides, as they did not help achieve convincing service lives.

Solution

After tests with different bearing types, drylin linear bearings proved to be the best solution. They allow for the longest service life, which is around three months. At first, that doesn't seem like much. However, if you multiply 50,000 strokes by 90 days, this results in 4.5 million working cycles and that in combination with dirt, high dynamics and alternating loads. The linear housings are equipped with liners made of wear-resistant iglidur J plastic and, thanks to the incorporated solid lubricants, do not require any external lubrication. As a result, no dirt sticks to them, maintenance is superfluous and the axes are guided with extreme precision.Krenzer is so convinced by the dry-running bearings that they are not only used on the removal units for the cover boards from the storage, but also for the feeding and exact positioning of the cover boards.

Gregor Krenzer, Managing Partner of Aloysius Krenzer KG