Technical data:

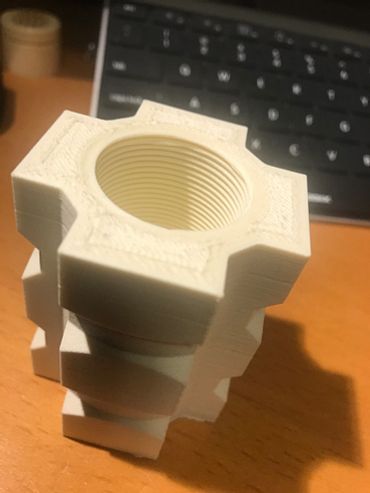

- What was needed: An alternative to metal ball nuts that can be manufactured independently using 3D printing

- Requirements: 100% lubrication-free and maintenance-free, quiet operation, easy to manufacture, smooth running, clearance-free

- Material used: 3D printing filament iglidur® i190-PF

- Success for the customer: In the design, there was no other way to achieve the set goal. The parameters were prescribed, and the final product had to work. Optimising the contact area was crucial to reducing friction. Thread surface hardening reduced it further. After several printing attempts, the print quality improved.

Do you need more information? Contact us here

Problem

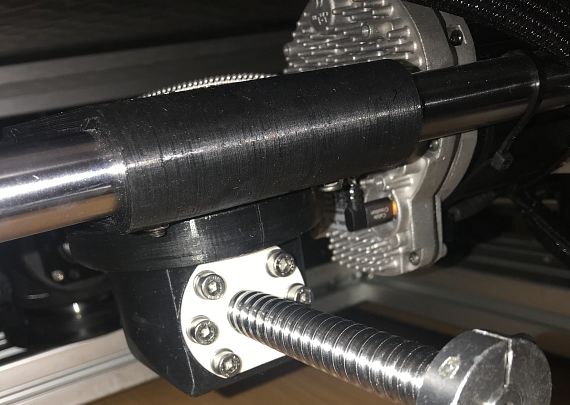

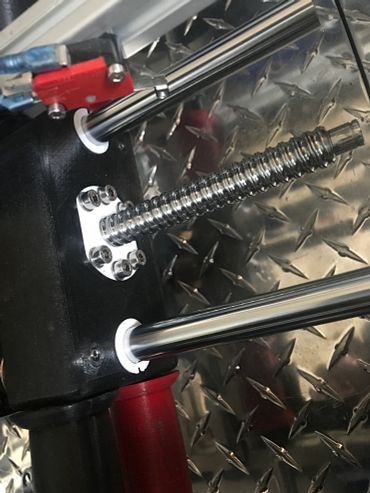

Volker Krebs of VKC Services Ltd from Canada needed a lead screw nut. Metal ball screw nuts are too heavy and also require regular maintenance and lubrication. In a 6DOF (6 directions of force) simulator, the noise from the ball screw can be very annoying over time. The simulators are used indoors and therefore operate in a constant temperature environment. The biggest challenge was to find the right tolerances to obtain a smooth-running lead screw drive with no backlash. The ball screw drive bearing converts rotation into linear motion. Their use in an actuator requires that they can withstand linear acceleration forces of up to 3g under various load conditions. The average motor speed is 800-1200rpm, but can be as high as 3000rpm. The load per drive is about 1500N.Solution

Volker Krebs has designed a replacement for a ball screw nut. The material for this is iglidur i190. The use of igus linear bearings and now iglidur i190 3D-printed polymer nuts makes the simulator a truly mechanically quiet simulator. It also integrated the actuator's internal slider into the nut design for ease of maintenance. In the design, there was no other way to achieve the set goal. The parameters were prescribed, and the final product had to work. Optimising the contact area was crucial to reducing friction. Thread surface hardening reduced it further.Further application pictures:

Products used

Do you have questions about drylin® lead screw technology?

Our expert Thorben Hendricks will answer all your questions about drylin lead screw technology. Just fill out the contact form and we will take care of your issue. We are looking forward to your message!► Request contact online

► Make an appointment

► Expert support upon request by phone or with the video chat function

► Order a free sample

Request expert support here