knife edge rollers for conveyor applications

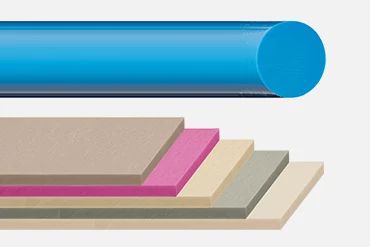

Knife edge rollers are small rollers which form a continuous

gliding edge on conveyor belts. It enables product to glide smoothly between belts. Unsurprisingly they are commonly found on the edge of conveyors, providing a lubrication-free and precise guide system.

igus® has developed a range of knife edge rollers in their iglidur® materials. These rollers offer a tight deflection radius and require a very low amount of drive power. They are easily assembled and are extremely cost effective. If we can't offer you a standard roller to meet your requirements we can custom machine one!

Would you like more information about iglidur® or do you need a consultation? Our experts will be happy to get in touch with you.

gliding edge on conveyor belts. It enables product to glide smoothly between belts. Unsurprisingly they are commonly found on the edge of conveyors, providing a lubrication-free and precise guide system.

igus® has developed a range of knife edge rollers in their iglidur® materials. These rollers offer a tight deflection radius and require a very low amount of drive power. They are easily assembled and are extremely cost effective. If we can't offer you a standard roller to meet your requirements we can custom machine one!

Would you like more information about iglidur® or do you need a consultation? Our experts will be happy to get in touch with you.

Contact an expert

knife edge roller options

A350 knife edge roller

- Compliant with EC regulation 10/2011 EC

- For use with temperatures up to +180 °C

- FDA compliant

Visit the shop

P210 knife edge roller

- Specialist for pivoting & rolling applications

- Belt deflection 100% lubrication-free

- Good coefficients of friction and wear

Visit the shop

H1 knife edge roller

- Endurance runner with high media resistance

- Very low coefficient of friction

- High resistance to temperature and chemicals

Visit the shop

Custom machined options

- Do you need a custom roller?

- We can design and machine a bespoke component for your application.

Find out more

What are the benefits of iglidur knife edge rollers?

Robust

Withstand high temperatures, strong vibrations and more.

Withstand high temperatures, strong vibrations and more.

Resistant to dirt

Can be used even in applications involving sand, swarf and dust.

Can be used even in applications involving sand, swarf and dust.

Corrosion-free

Are corrosion-free and media-resistant for use under water.

Hygienic

Do not require external lubrication and are FDA-compliant.

Do not require external lubrication and are FDA-compliant.

Light

Lighter than comparable guide rollers with metal

Lighter than comparable guide rollers with metal

Versatile

Different materials allow for an exact customisation to your application.

Different materials allow for an exact customisation to your application.

Knife edge roller applications

Krones relies on iglidur knife edge rollers

Regarding Variopac Pro, a fully automatic all-rounder packaging system, Krones faced a problem in 2005: the system's performance had to be increased by 20 packages per minute. Hence, there was an urgent need for action during the deflection of the conveyor belts. Originally, metal rollers with needle roller bearings were used here; however, they couldn't fulfil the higher performance requirements and were cost-intensive. When looking for an alternative, Krones Design Engineer Jürgen Werner came upon the products from igus GmbH.

Find out more

The knife edge rollers are ideal for these conveyors as they allow the following:

- Easy gliding

- Low coefficient of friction

- No lubrication.

- Hard wearing

- Easy to replace.

Buy now!

Use in food processing

It is not only raw bakery products that present the machine manufacturer in the food sector with considerable challenges. If two conveyor belts are butt-jointed to each other, the radii of the guide rollers result in a gap between the two belts. The risk: sensitive products, such as raw pasta products, simply slide into the gap between the conveyor belts.

To transfer these products safely from belt to belt, the deflection radii of the conveyor belts and the gap between the belts must be kept as small as possible.

To transfer these products safely from belt to belt, the deflection radii of the conveyor belts and the gap between the belts must be kept as small as possible.

Food industry

Food and Packaging industry

Conveyor rollers are essential in the Food and Packaging industry. Having a large range of FDA and EU compliant knife edge rollers allows customers to have peace of mind that there is no contamination.

The iglidur® A180, A350 and A250 knife edge rollers are all FDA/ EU 10/2011 compliant.

All FDA products have full certification and can be found on the website.

The iglidur® A180, A350 and A250 knife edge rollers are all FDA/ EU 10/2011 compliant.

All FDA products have full certification and can be found on the website.

Buy now!