Technical data:

- What was needed: An espresso machine that can be operated manually and without electricity

- Requirements: Food-compliant, resistant to boiling water, non-corrosive

- Products used: dryspin® trapezoidal lead screws with 12x3 threads

- Success for the customer: igus solutions are used in the crank mechanism. Turning the crank moves the lead screw, generating pressure so that the coffee can be prepared correctly.

Go to application

The Kazak espresso machine

Description of the application. What is the function of the application? Where is the application used?

The product is a manual espresso machine that can be used to make espresso under almost any conditions - both at home and outdoors. The workmanship in every detail resulted in a high-quality, reliable, extremely stylish device.

What are the usage/environmental conditions at the end user's location? What challenges did you have to overcome to adapt to those conditions?

The espresso machine requires no electricity to operate and can be taken anywhere. The materials used must be approved for food contact and withstand the boiling water poured into the machine.

What requirements did dryspin lead screw technology have to meet?

The most important requirement was complete corrosion protection and no lubrication of the moving parts.

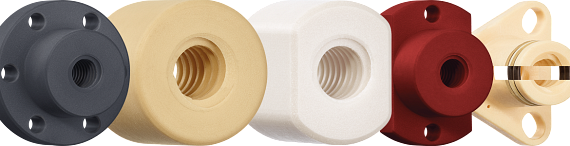

What dryspin lead screw technology solutions do you use?

A 12×3 PTGSG trapezoidal lead screw made of stainless steel was used, which moves in a polymer block. The trapezoidal thread cross section is an isosceles trapezoid with an angle of 15°. The thread angle is 30°. The trapezoidal lead screw has a larger diameter and greater pitch than standard threads do. The pitch angle is smaller than the arctangent for single start trapezoidal lead screws. This ensures self-locking.

Where was the lead screw used? How did dryspin products solve the problems?

The dryspin solution is used in the crank mechanism. Turning the crank generates the pressure necessary for the coffee to be prepared correctly.

Do you have questions about drylin® lead screw technology?

Our expert Thorben Hendricks will answer all your questions about drylin lead screw technology. Just fill out the contact form and we will take care of your issue. We are looking forward to your message!► Request contact online

► Make an appointment

► Expert support upon request by phone or with the video chat function

► Order a free sample