iform – Toolmaking by igus

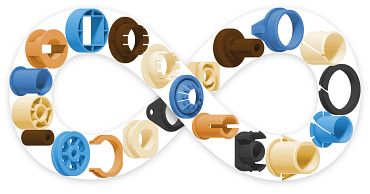

Precise tools are the prerequisite for high-quality components. We at igus manufacture the tools for our injection moulding in our own in-house iform tool shop. From tool development, production and sampling up to quality control with computer tomographic support, a tool is made completely by our hands. This gives us the opportunity to implement requests for individual components at short notice and in full quality. Since the tool shop is involved in the development and consultations with customers at an early stage, we can offer not only suitable materials but also the appropriate tool manufacturing processes to reduce overall costs. Depending on the order volume, a mould can also be produced as print2mold in 3D printing, naturally also at our premises and from our proven high-performance polymers.

Main tasks

- Development, production and sampling of tool technology for all igus injection moulding products

- Enabling the fastest possible tool repairs and maintenance to ensure delivery capability for our customers

- Design of technical innovations together with sales, development and production

100

Staff1,550 m2

Area32

Machine toolsOver 3,000

Tool extensionsOver 1,000

Injection moulded parts per yearExcellent toolmaking

RWTH Aachen and Fraunhofer Institute choose Toolmaker 2022

Every year, the "Excellence in Production" competition is organised by the Machine Tool Laboratory WZL of RWTH Aachen University and the Fraunhofer Institute for Production Technology IPT. The motto: Learn from the best! We are delighted that our toolmaker iform has won this year in the category "Internal toolmaker with more than 50 employees". One of the decisive factors for the jury was the focus on short throughput times and process standardisation. The FastLine, in which we guarantee the supply of tools for individual customer special parts for volume production within seven days, particularly convinced the jury. See for yourself the advantages of our excellent toolmaking.

You can see what makes our toolmaking special in the video on the left.

You can see what makes our toolmaking special in the video on the left.

New manufacturing line for new service

igus FastLine - injection-moulded special plain bearings in seven days

With the FastLine service, you have the possibility to receive injection-moulded plain bearings and thrust washers in a maximum of seven days. You can easily find out whether injection moulding or a different manufacturing method is worthwhile for you in the iglidur plain bearings designer: the online tool offers a price comparison of all igus manufacturing methods and a comparison with our standard product range. That way, you can always keep an eye on the best price.

Find out more about FastLine now

Experience the igus factory in 360° now

What actually happens in our factory at our headquarters in Cologne? Dive into our 360° VR world and discover the most diverse stations from injection moulding to the tool shop, to quality control or our laboratory. All stations are also accompanied by interesting information about the factory and the machines.

Start 360° tour now

Step by step to the finished tool

Tool simulation and development

The combination of detailed simulation of the parts and decades of design experience of our employees enables tailor-made tool concepts. On the basis of early co-ordination between part and tool design, the production effort can be optimised, saving time and costs.

Project planning

Our digital project planning forms the basis for high resource efficiency. The virtual representation of all production processes in real time makes it possible to plan the project process taking into account all available machine and employee capacities. In this way, it is possible to achieve optimum machine utilization and to reduce throughput times to a minimum.

Tool production

Our machinery, comprising 27 systems, is equipped with state-of-the-art processing machines and a wide range of production technologies. Thanks to the networking of machines and the use of automation, we are able to produce the most demanding components in the shortest possible time while complying with the tightest tolerances.

Sampling in the technical centre

The process stability of the tools is validated in iform's own technical centre. Injection moulding machines with up to 100t clamping force are available for commissioning and optimisation of the injection process. The top priority when sampling the tools is always to achieve the optimum in terms of economy and component quality.

Quality assurance

By using tactile 3D measurement and advanced computer tomography (CT) we ensure the best possible quality and function of our products. The extensive possibilities of part-to-CAD comparison, inclusion analysis and assembly inspection support us in correcting the tools as required.