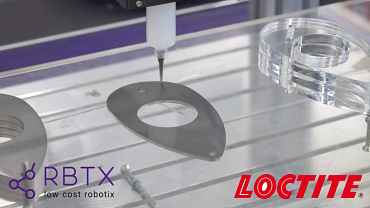

Gluing linear robot - RBTX/Loctite

What was needed:

automated palletising of components & gluing

Requirements:

modular system that can be reprogrammed and is compatible with various grippers

Material:

igus room linear robot DLE-RG-003 with suction pad and dispensing unit

Industry:

furniture production/metal processing

Success for the customer:

simple plug and play linear robot for automating tedious manual work in large-scale production

automated palletising of components & gluing

Requirements:

modular system that can be reprogrammed and is compatible with various grippers

Material:

igus room linear robot DLE-RG-003 with suction pad and dispensing unit

Industry:

furniture production/metal processing

Success for the customer:

simple plug and play linear robot for automating tedious manual work in large-scale production

Go to application

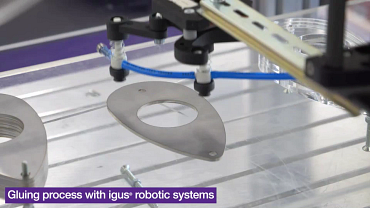

During the application, individual components, in this case glass elements and aluminium plates, are assembled from a storage unit and glued two-dimensionally. After this, they are transferred back to a storage device. The resulting components are part of a special North German lamp.The problem

Due to the variability of the components in shape and size, a flexible system is required to implement the production processes.An additional challenge is the even application of the adhesive seam, since both the positioning and the quantity used are important here. Protruding adhesive seams would result in an increased post-processing process.

The solution

An igus room linear robot in combination with a suction pad and a dispensing unit from LOCTITE. The whole thing was achieved within a compact robot cell to protect the production process from contamination or unwanted manual intervention.Low Cost Automation shop

Cost-effective robotics for your automation project

You can find the right robot for your individual application in our online shop.Browse, get information and order easily.

To the shop