Energy supply installed cost-effectively and in a flash in SRU lanes

The autoglide 5 e-chain system proves itself in productive use at Gebhardt Intralogistics

Profile

- What was needed: energy supply for storage and retrieval units, alternative to busbar system

- Requirements: cost-effective when used in short lanes, maintenance-free, easy to clean, simple and quick to install

- Application area: intralogistics

Problem

In the technology and test centre that Gebhardt operates in Sinsheim and uses for production supply, a Cheetah storage and retrieval unit for automatic small parts warehouses is installed in addition to pallet conveying and shuttle technology, which is characterised by its particular speed, among other things. Conductor rails are traditionally used for power transmission in busbar systems, but they have a number of disadvantages. They require regular cleaning and maintenance, the pantograph contacts are prone to wear and the price for short lanes is relatively high. In addition, they involve a high effort for planning, project planning and installation with all the associated components, such as light barrier, transmitter, receiver etc.Solution

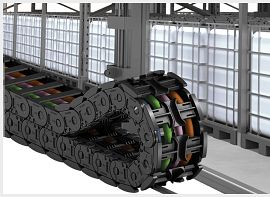

igus has developed autoglide 5, an innovative energy supply system for horizontal use that works entirely without a guide trough. It is built over a rope stretched on the floor. The energy chain with cables for energy, data, liquids or even air can travel safely and quietly at 4m/s on this. Without a guide trough, 50% of the floor remains free, the cleaning effort is reduced and maintenance is eliminated. Another highlight: the assembly is simple and done in a flash. The complete autoglide 5 system, including all cables, was ready to install at Gebhardt in three hours. It would have taken 1.5 days for a busbar system, not counting the data transmission setup. Gebhardt has now been using the igus system for a year and is very satisfied.Further information

autoglide 5

Functionality, advantages, areas of application ... more about the innovative energy supply system without guide troughFind out now

Products for intralogistics

Durable components for SRUs & shuttles, industrial vehicles, lifting tables and conveyor technologyDiscover now