Successfully used in fluid technology

Our products have already been tested thousands of times in practice and proven successful in the agricultural industry in numerous applications. By switching from metallic to lubrication-free dry-tech bearing products, our customers have been able to improve the technology of their hydraulic, pneumatic and HVAC systems and reduce costs: with longer service life and less maintenance. In the following, you can find a selection of customer applications that have already been realised.

Valves

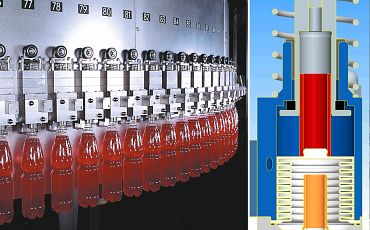

Durable guide rings in valves for emptying bottles

The Rink company relies on plain bearings from igus in its beverage machines. In the valve heads used for emptying bottles, chemical-resistant iglidur J guide rings replace the conventional piston rod seals that were previously used, which often did not provide the desired stability.

More about the application

Chemical-resistant special bearing in beverage filling valve

KHS' filling line for beverages containing CO2 uses a patented filling valve in which each PET bottle is pressed on by the product pressure. The designers were looking for a bearing that could withstand temperatures of up to 140°C and was resistant to all cleaning agents used in the beverage industry. The solution: a plain bearing in a special shape made of iglidur X material.

More about the application

Clean valve guide in ice cream filling plant

At Big Drum Engineering, O-rings were initially used to support and guide the piston in the valve, which is used to fill ice cream with pieces of fruit, but these quickly wore out. The designers finally replaced them with a new special seal and iglidur J plain bearings, which serve as a support and guide ring for the piston. Wear went down to a minimum and there are no more piston jamming.

More about the application

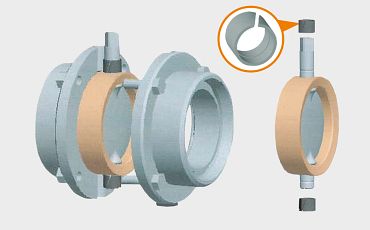

iglidur plain bearing on the butterfly valve: quickly mounted and securely fastened

In its disc valves, the company Nocado relies on iglidur G plain bearings in a special design. Fitted with a slot and spring, the bearings quickly snap onto the grooved shaft ends of the disc without the need for tools. This eliminates the need for a third hand to keep the bearings from falling out during installation or maintenance of the butterfly valves.

More about the application

Pumps

Protection against rapid wear in innovative dosing diaphragm pump

Our iglidur X plain bearings resistant to chemicals and temperature are also used in the ecoflow dosing diaphragm pumps from LEWA. Installed in the engine, they minimise wear on the piston rod pin.

More about the application

Infusion pumps: Plastic plain bearings help with high-precision dosing

Specially manufactured clip bearings made of iglidur J material are used in infusion pumps from B. Braun Melsungen AG. They are easy to install in the tight installation space and do not require external lubrication, which is essential in this application to avoid contamination. Thanks to its low friction coefficient, the infusion pump can work smoothly despite very short strokes.

More about the application

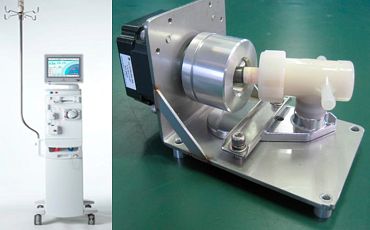

Dialysis pump moves maintenance-free with lubrication-free spherical plain bearings

Iwaki originally used metal spherical bearings in its dialysis pumps, which required constant relubrication. They then tested dry-operating igubal spherical bearings in a pump that was moved for more than 10,000 hours in a temperature cycle from -10 to +60 degrees - with success. Since switching to igubal, the pumps have been running reliably and trouble-free for many years.

More about the application

Long-lasting bearings in solar thermal water pump for developing countries

In order to implement pivoting and linear movements in the complex gearbox unit of their solar water pump, the designers at BSR Solar Technologies were looking for robust, cost-effective plain bearings and found what they were looking for at igus. Several flanged and clip bearings made of various iglidur materials ensure reliable movement without maintenance effort.

More about the application

Consumers/components

Hydraulic cylinders in tipper vehicles reliably mounted without grease and rust

The company Wye uses hydraulic cylinders in scissor lifts to provide the lifting mechanism for tipper vehicles. As the metal bearings regularly rusted and wore out, they quickly switched to our lubrication-free igutex TX1 high-load bearings, which are extremely wear-resistant and dimensionally stable thanks to their long-fibre winding design.

More about the application

Economical alternative to brass bushes in special hydraulic cylinders

In its special hydraulic cylinders, the Chapel Group relies on iglidur G plain bearings. In addition to short delivery times, they also offer technical advantages. Compared to the brass bushes previously used, they are significantly more economical and, with diameters of 20 to 45mm, are extremely wear-resistant and weatherproof.

More about the application