Lead screw technology in a fall protection platform

Technical data:

- What was needed: A solution that provides more safety when working at height, for which the modular SRU safety platform for Euro pallet high-bay warehouses is used today

- Requirements: Self-locking, maintenance and lubrication-free, withstanding high temperature differences and moisture, no corrosion

- Products used: dryspin® LH/RH lead screws, cylindrical lead screw nuts, fixed and floating bearing lead screws

- Success for the customer: drylin lead screws and nuts from the full product range are available for every technical requirement. They are available in several materials and various designs. "The trapezoidal lead screws with matching nuts are a safety-relevant component," Adriany says. "They cover a wide variety of geometries without bending."

Need more information? Contact us here

Platforms that save lives

igus lead screw drives ensure smooth operation in safety platforms in high-bay warehouses

High-bay warehouses are emerging everywhere. Maintaining them is often like a tightrope act. A fall protection platform developed by MehrTec GmbH makes it safer. The platform's core is a clamping mechanism for fixing the modules. The mechanism consists of lubricant-free trapezoidal lead screws in combination with cylindrical nuts. This igus system solution ensures the necessary safety. It removes danger to life and limb."The fall protection platform's development goes back to a height rescue exercise in a high-bay warehouse," says Dipl. Ing., Dipl. Wirtsch. Ing. Udo Adriany, Managing Partner of MehrTec GmbH in Müsch (Germany). "A few years ago, there was a simulation in which a worker equipped with safety harnesses had to be rescued from a great height in a high-bay warehouse. Although the rescuers were trained, it took a total of 20 minutes. If it had been real, the consequences would have been fatal. Due to suspension trauma, circulation in the leg area is cut off by body weight, the person loses consciousness, circulation collapses, and potentially he dies after rescue."

The legal situation is clear: High-bay warehouse operators are responsible for occupational health and safety. This called for a solution that provides more safety for work at height, for which the modular SRU safety platform for Euro pallet high-bay warehouses is used today.

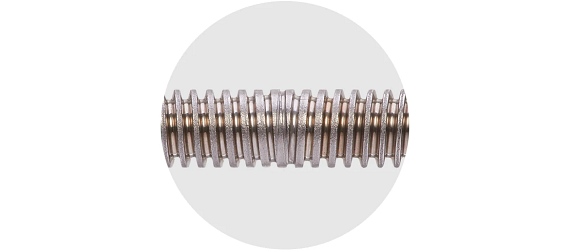

Trapezoidal lead screws for quick fixing

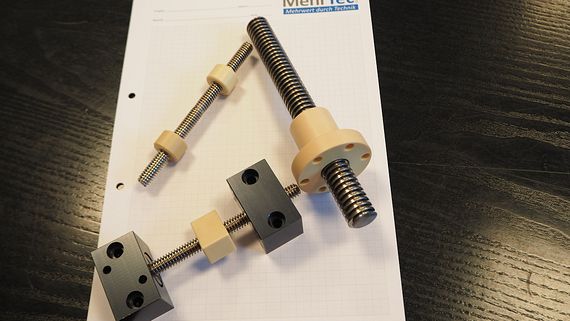

The individual modules can be automatically positioned anywhere in the high-bay warehouse with the load suspension device of the storage and retrieval unit (SRU) and securely fixed with the clamping mechanism. The main components of this patented solution are two single-start drylin trapezoidal lead screws for each module. They are self-locking, meaning that the flank angle and the sliding friction prevent the nut and lead screw from moving without outside force being applied. There are also drylin lead screw nuts made of iglidur J that turn clockwise and anti-clockwise. The complete solution requires no maintenance or lubricant and is particularly suitable for applications in cold (-30°C), heat (+80°C), and humidity, such as food warehouses. Metallic systems often suffer corrosion in such applications.This igus solution's design advantage is that drylin lead screws and lead screw nuts from the full product range are available for any technical requirement. It includes lead screw nuts from five different lubricant-free iglidur high-performance polymers, with trapezoidal and high helix threads, a cylindrical design, or as flanged variants. "The trapezoidal lead screws with matching nuts are a safety-relevant component," Adriany says. "They cover a wide variety of geometries without bending."

Lead screw bearings are also used as fixed and floating bearings in the SRU safety platform. They clamp the lead screws so that they are secured in the fixed bearing to prevent the threads from being worked out. The floating bearing is equipped with an igus plain bearing for additional lead screw support. It can also expand and is easy to adjust from the outside.

Ready-to-go built-in part

"The highlight of the platform is the clamping mechanism," says Adriany. "The modules can be fixed in any position, manually or automatically." This ensures great flexibility in everyday operations. The igus solution requires no lubricants or maintenance, is more economical than a recirculating ball bearing system and performs well. It is a special lead screw machined from both sides with a simple transition point in the middle. It is completely processed at igus machined to the relevant specifications, and the customer receives a ready to install system. Delivery time is between two and three weeks. igus always provides all CAD data so that the customer can enter them directly into his system."Although it is basically a mass-produced product, we were completely won over by the conscientious processing," says Adriany. "A lot of unnecessary handling and delays are completely eliminated." The collaboration between the two companies is exceptionally good. "All technical statements are completely reliable. The contact persons in the office and the field are competent and dependable", says Adriany.

Around 50 SRU safety platforms are already proving their functionality in the food, chemical, and pharmaceutical industries and in machine and plant engineering.

Maintenance at great heights

Storage and retrieval machines in shelf lines must be regularly maintained and any malfunctions quickly eliminated so that there are no downtimes and/or failures. This often involves adventurous conditions. Makeshift solutions are common. This is usually not only tedious and time-consuming, but often life-threatening. The high-bay warehouse fall protection platform enables the installer to reach his workplace comfortably and move around safely. A few simple steps even produce a bridge connecting opposite shelves. Telescoping bridge modules are also possible. The solution not only makes work much easier and increases occupational safety in everyday operations, but also saves time and money.The safety platform is individually adapted. "As an individual solution, each clamping mechanism maps the actual conditions in the high-bay warehouse racking system," says Adriany. "We offer customers from a wide range of industries a modular system that can be variably adapted." The clamping mechanism is used to fix the individual module to any point on the high-bay warehouse. The main components - the two trapezoidal lead screws with left-hand and right-hand threads and the trapezoidal lead screw nuts - ensure that the platform can be securely fixed. There is a bottom clamp on the lead screw nuts which clamps to the shelf's longitudinal profiles like a vice and prevents bending. "The self-locking nature of the lead screw makes it a relatively simple yet highly efficient mechanism," says Adriany. Despite the enormous forces acting on the lead screws and the nuts (max. stat. axial F=3,519N per nut), the tensioning always remains constant, ensuring the necessary safety. Integrated optical display elements also make the high-bay warehouse safety platform easier to use.

It was introduced for the first time this year at LogiMAT, and demand is steadily increasing. TÜV and Berufsgenossenschaft BGHW, a German association for commerce and goods logistics, also confirmed that the SRU safety platform complies with the technical rules for operational safety, the guidelines for equipment and systems for rack operation, and even the strict requirements of Germany's Industrial Safety Regulation (Betriebssicherheitsverordnung).

Warehouse downtime is expensive. A discount grocer, for example, insists on timely delivery. Safety platforms play an important role in minimising downtimes and increasing work safety in high-bay warehouses. They can save lives. In this environment, igus linear technology that requires no lubricant or maintenance makes an important contribution to guaranteeing continuous functionality and safe, fast work.

Warehouse downtime is expensive. A discount grocer, for example, insists on timely delivery. Safety platforms play an important role in minimising downtimes and increasing work safety in high-bay warehouses. They can save lives. In this environment, igus linear technology that requires no lubricant or maintenance makes an important contribution to guaranteeing continuous functionality and safe, fast work.

Do you have questions about drylin® lead screw technology?

Our expert Thorben Hendricks will answer all your questions about drylin lead screw technology. Just fill out the contact form, and we will take care of your issue. We are looking forward to your message!► Request contact online

► Make an appointment

► Expert support upon request by phone or with the video chat function

► Order a free sample

Request expert support here