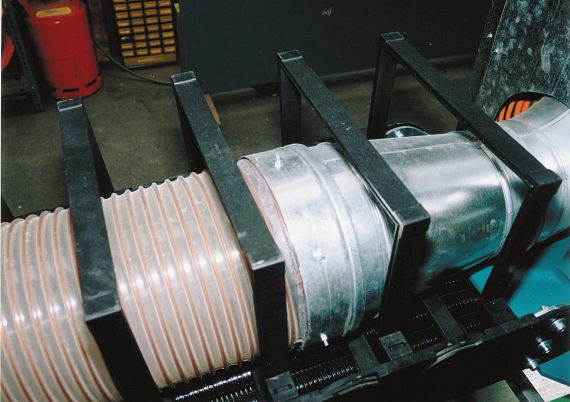

Energy chain with piggyback suction hose

A new type of energy supply system is made from standard components

Special construction or standard solution? Customers want technically optimised machines without special design problems such as time-consuming spare parts procurement and high development costs. What initially looks like squaring the circle can be achieved, as Westphal Maschinenbau, based in Hamelin, Germany demonstrates with igus components. A new type of energy supply system was created from standard parts, and its piggyback principle finally gives the large-volume suction hoses in wood and sandwich processing a defined place and creates space for refinements."Open window" for customers

Westphal Maschinenbau company policy focuses consistently on quality, openness, and customer benefits, making the company successful in a difficult environment. It is important to use both the best components and standard elements: "More precise and better components save follow-up costs at all stages," says Rene Westphal. For example, installed racks must have minimum tolerances and a measurement protocol. This reduces follow-up costs in assembly and setup and continues through to production. His machines are so accurate that he tests them in practice before delivery by cutting special threads – an unusual measure for machines of these dimensions. The CNC machining centre shown has a linear robot design and seven axes with traverse paths of 15,500 x 3,200 x 450mm (XYZ) for machining caravan side parts and floors. Its main use is processing aluminium sandwich elements. When it comes to direct customer contact, the company's CEO also goes beyond the usual. His openness extends to revealing all machine parts, enabling the customer to buy any spare parts himself. The machines are also prepared for retrofitting. Of course, this requires standard components – including in the energy supply system!

"The egg dance is over"

Large suction devices for extracting swarf are characteristic of wood, aluminium profile, and sandwich element processing. But suction hoses hanging from the ceiling were simply not feasible if machines were to be increasingly modern and continue to deliver higher performance. A solution was urgently needed. "It gets tricky with just two hoses," says Westphal. "So we looked around the market for a solution." And they did it with characteristic Westphalian openness. Westphal wanted his energy supply system supplier to be as competent and transparent as he is with his customers. "We were immediately impressed by the igus sales engineer. He came right away and submitted a qualified offer within a few hours. And when questions arose during installation, he came and supported us. We now have a solution that puts an end to the waffling and enables us to refine our machine however we want – with more axes (absolutely or per linear robot) and longer travels."So what exactly was the solution?

Piggyback to the destination

The search for the ideal guidance system for the suction hoses did indeed include the following points: It needed to- consist of standard components

- guide suction hoses of 250mm diameter

- require a minimum of space

- guide other cables of much smaller diameter

The solution was not trivial because the extraction hoses with a 250mm diameter would theoretically require very large energy supply systems which would therefore be very expensive and much too large for the load.

The Type 1600.40.250.0 energy supply system development was a cooperation between Westphal Maschinenbau and igus that resulted in a solution based on the piggyback principle. It is made entirely of plastic and requires no metallic bolted connections, so it is very easy on cables and hoses. It

- reliably separates the large, relatively fragile hoses on one side of the energy supply system from the pneumatic and energy cables on the other.

- guides hoses with large diameters – in this case 250mm – with minimal material expenditure, making them lightweight.

- is based on the igus modular energy supply system, which ensures spare parts supply.

"In fact, our modular system is the only thing that makes this solution possible," says Michael Blass from igus. "We have more than 43,000 parts, so we can also implement special solutions using our modular system. We have rearranged standard components so that the customer has no waiting time for reordering."

Lean solution

The piggyback solution with the igus energy supply system has another important advantage: it is very lightweight. The linear robot's servo motors thus need less than 1% of their power to move the energy supply system. After all, 25 cables (in addition to the suction hoses, there are fibre optic, energy and pneumatic cables) are guided and moved at up to 60m/min at an acceleration of 1.5m/s². This solution supports only the energy supply system's upper run. The extender crossbars are so rigid that they require no additional structural elements to ensure lateral guidance and absorb vertical load over the entire travel (16 metres). But these values do not come close to exhausting igus energy supply system performance.