Energy chains and cables for HUNGEXPO's innovative multi-purpose hall

Plastic e-chains and chainflex special cables for complex installation under the hall floor

Winner of the 2022 gold vector award: For a new HUNGEXPO multi-purpose hall in Budapest, our team was able to be part of the process from the planning stage to final installation. The huge auditorium has rows of seats on 43 platforms that can move flexibly, transforming the room into a ballroom if required. The people responsible brought our project team on board for the complex cable guidance and the many cables. The application uses our plastic energy chains and chainflex® control, data, and bus cables.

Profile

- What was needed: Plastic energy chains from the E4.42 series, E2/000 overview, and chainflex® special cables, delivered as a fully harnessed complete readychain® system

- Requirements: The floor elements required particularly reliable cable routing, failures should be avoided at all costs, and maintenance intervals should be kept as long as possible. The project also required quick and easy installation.

- Industry:Theatre and stage construction

- Success for the customer: The energy chains respond smoothly to the movements of the floor panels and allow a long service life. The chainflex cables are resistant to torsion and wear. Delivered as a pre-assembled readychain energy chain system, quick installation on site was achieved.

Problem

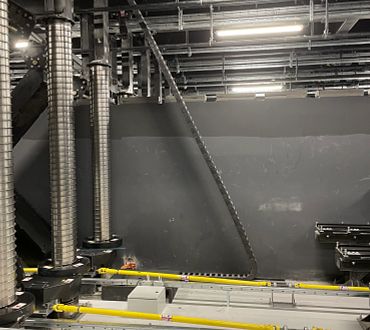

HUNGEXPO in Budapest is the largest congress and exhibition centre in Hungary. From 2019 to 2021, the concept of the huge exhibition space was revised so that it now shines in a whole new splendour. The programme also includes a new and modern state-of-the-art auditorium. But the real sophistication behind the 1,800m2 multi-purpose hall with a capacity of 2,048 people is only revealed at second glance. The rows of seats, which are located on 43 movable platforms, can disappear under the floor with little effort. A theatre can thus be converted into a ballroom in just 8 minutes. All it takes is one person to operate the sophisticated system and — depending on the specific occasion and space requirements — have eight different configurations carried out.The machinery that makes all this possible is of course out of sight under the hall floor. And it goes without saying that supplying the extremely mobile rows of seats with energy and signals is anything but easy. This allows the rear rows of the auditorium to move up to 5m in height. In addition, numerous cables are also required for lighting and the sound system of several rows.

The ambitious project therefore also required cable routing that guides the large number of cables under the hall floor in a space-saving, safe and durable manner. Overall, maintenance intervals should be extended and the installation time of the system should be kept as short as possible.

Solution

Good HUNGEXPO-igus® experience in previous projects made cooperation obvious here, too. Plans drawn up at an early stage took into account the environment and the machines for the safest, most space-saving cable guidance possible. After several test installations in the especially demanding areas, the products for implementing cable guidance were finally identified and the project was ready to start.Since then, dozens of energy chains from the E4.42 series and the E2/000 overview have formed the heart of the cable guidance hidden from Expo visitors. The particularly flexible connection between the supply points on the floor and the adjustable rows of seats supports fluid movement and continuous mechanism operation. Control, motor, and bus cables from the chainflex® range are used in the energy chains. The cables are specifically designed for energy chains and especially well protected against movement-induced wear and torsion. Since they were delivered pre-assembled in the chain – as a so-called complete readychain® system – the installation was user-friendly and quick to implement. The result is cable guidance that reliably follows all movements, allows long maintenance-free phases, and thus saves the operator costs.

Attila Lukacs, GEPBER-Szinpad Kft.