Energy chain E4Q.L

Lightweight with large-scale inner heights - the best combination of strength and low weight. Highly dynamic, save up to 40% assembly time ► now openable by hand

Based on the successful E4Q, the first sizes of an L variant with an inner height of 64/58mm are now available. Easily openable by hand with the quick-opening crossbar. Uses E4Q.58/82 crossbars, so a complete width spectrum is directly available.

The bio-mechanic design increases strength and extends service life while reducing weight. The quick-opening crossbars allow the chain to be opened/closed easily and intuitively. Another advantage of the growing E4Q modular system is that no new crossbars need to be developed for the new E4Q.L series because the E4Q.58's have been used. The complete range of 29 widths, from 100 to 500mm, is thus immediately available

The bio-mechanic design increases strength and extends service life while reducing weight. The quick-opening crossbars allow the chain to be opened/closed easily and intuitively. Another advantage of the growing E4Q modular system is that no new crossbars need to be developed for the new E4Q.L series because the E4Q.58's have been used. The complete range of 29 widths, from 100 to 500mm, is thus immediately available

Request energy chain E4Q.L now

Product range:

| Part No. | Inner height [mm] | Outer height [mm] | Inner width [mm] | Outer width [mm] | Bend radii [mm] | Pitch | |

|---|---|---|---|---|---|---|---|

| E4Q.64L | 64 | 90 | 100 - 500 | 126 - 526 | 135, 150, 175, 200, 240, 250, 300, 350, 400, 450, 500 | 100 |  Request now Request now |

| Part No. | Inner height [mm] | Outer height [mm] | Inner width [mm] | Outer width [mm] | Bend radii [mm] | Pitch | |

|---|---|---|---|---|---|---|---|

| E4Q.58L | 58 | 84 | 100 - 500 | 125 - 525 | 100, 135, 150, 175, 200, 240, 250, 300, 350, 400, 450, 500 | 91 |  Request now Request now |

E4Q is successful - so why the L version?

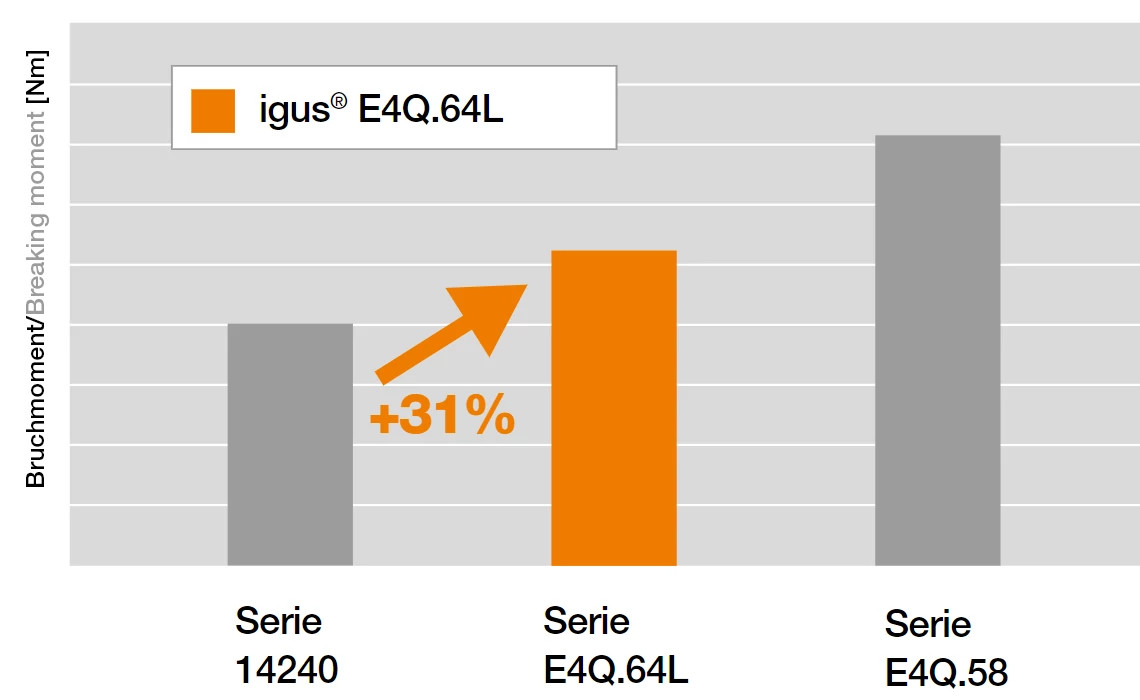

Many applications do not need the E4Q's thickness at all. Energy chains with a smaller wall thickness are sufficient to guide the cable packages. This is especially true of unsupported energy supply systems with low or medium loads, such as those in machine tools, woodworking equipment, and car washes. igus has developed the L version to offer users the advantages of the E4Q in these applications as well, and at an attractive price. Depending on the width, the E4Q.L costs about 15-20% less than the E4Q.58, but is about 40% stronger than the predecessor models (the "E4 Light" and "E4.1 LEAN"). "Thanks to the outstanding strength of the E4QL, we can serve completely new applications more cost-effectively than ever before while offering the proven E4Q advantages," says Christian Ziegler, Head of e-chain® Product Management.New stop-dog system

"We completely rethought the stop-dog system. Development goals were more strength and service life than the two-stop-dog predecessors while retaining the option of a Reverse Bend Radius (RBR)," says development engineer Stefan Strack. Reverse Bend Radius means that the energy chain can bend in two directions. The result of this development process is the first igus energy chain with three stop-dogs. To the proven inner/outer link principle has been added a clever, innovative Reverse Bend Radius option: the inner link continues to determine the chain's bend radius via the size of the stop-dog pocket. For the first time, the outer link is used to implement the Reverse Bend Radius. Reducing the size of the stop-dog allows the chain to be bent backwards at predefined angles.

Tech up

- More room for cables thanks to the greater inner height (64mm) and reduced weight

- Proven E4Q design and approx. 10% stronger than the previous 14040 series

Cost down

- Reverse Bend Radius applications possible as standard without conversion/retrofitting

- Depending on the width, around 10-15% more cost-effective than the E4Q.58 thanks to slimmer side links

- 40% stronger than the predecessor models (E4 Light and E4.1 LEAN)

Proof

- Tested and developed in the igus laboratory:

Sustainability

- Reduced use of materials thanks to L design (about 15% lighter than E4Q.58 with the same width)

- Have your energy chain recycled at the end of its life cycle with the igus chainge recycling program. No matter what manufacturer. You will receive a voucher

Proof from the igus® test lab

Easy e-chain® extension

Extension link for the E4Q.L

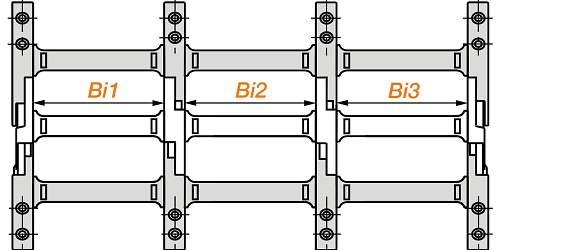

The extension link can be used to easily extend an existing e-chain® configuration in order to guide a large number of cables or especially heavy cables in one chain.- Guide additional cables and/or implement a higher fill weight

- The extension link makes an additional e-chain® unnecessary

- Further optimisation based on the tried-and-tested E4 extension links, which are already used in numerous applications

Product range:

| Part No. E4Q.58 extension link | Part No. E4Q.58.L extension link | Part No. E4.56 extension link | Part No. E4/light extension link | ||

|---|---|---|---|---|---|

| E4Q.58.Bi1/Bi2/Bi3.RRR.0 | E4Q.58L.Bi1/Bi2/Bi3.RRR.0 | E4.56.Bi1/Bi2/Bi3.RRR.0 | 14040.Bi1/Bi2/Bi3.RRR.0 |

The special design of the E4Q energy chain

E4Q energy chains

E4Q series energy chains have been developed to offer the best possible solution for unsupported and long travels. Based on the robust E4.1 energy chain standard that has been proven for over 12 years, the new series brings a long service life and a high degree of modularity.Buy E4Q-series energy chains now

You might also be interested in

Energy chains shop

Buy energy chains now