dryspin® lead screw drives on trains

Technical data:

- What was needed: no sticking or misalignment during continuous operation

- Requirements: Lightweight, weather-resistant, few components, low clearance height, reduced costs

- Products used: Stainless steel dryspin® lead high helix lead screws, dryspin® lead screw nuts made of iglidur® J

- Customer success: by substituting the belt drive, this reduces weight, the number of components and ensures a compact system compared to the more expensive modified drive concept. The simplified guidance system eliminates sticking.

To gap bridging

The sliding steps are used in trams, suburban and underground trains, in regional trains as well as high-speed trains. Two versions were developed with an eye to necessitating as few major adjustments as possible. With an installation height of only 50 millimetres for sliding steps up to 1,400 millimetres wide and 350 millimetres extension width in the standard version, they are very impressive on the market. The extension width of the sliding step depends on the infrastructure of each station. In addition to the standard solution, a second version with a longer extension width is being developed. The requirement profile of the railway builder and rail operator is as follows:

- Flawless functionality despite high temperature fluctuations and a wide range of dirt

- Low life cycle costs due to freedom from maintenance

- Completely lubrication-free

How the sliding step works

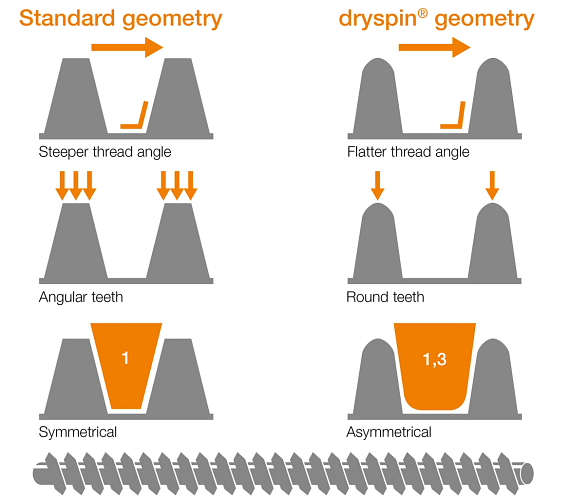

The sliding step is moved with the central lead screw drive with its no-seizing guide system. The locking module is also designed to require absolutely no maintenance or adjustment. The lead screw holds the sliding step in any position. It must be able to withstand heavy steps or swinging motions at all times. But there are even more difficulties. If there is a power failure, the running board can be retracted manually. Then the lead screw has to work in reverse without jamming. The high helix lead screw, which is used in the non-hermetically sealed sliding step, is lubrication-free and therefore maintenance-free. It achieves higher efficiency with a flatter thread angle. Asymmetric geometry between lead screw and nut increases service life. Rounded tooth flanks ensure better running performance and quiet, vibration-free operation. The associated dryspin® flanged lead screw nut made of iglidur® J ensures high efficiency with virtually no wear. Dry operation ensures that nothing sticks. The special sliding block – also made of iglidur® J – absorbs the forces when the lead screw or the sliding step extends. The cost-effective plain bearings made of the iglidur® G universal material are also used. They are maintenance-free, abrasion-resistant and, like the other components, insensitive to dust, dirt, moisture, and cleaning chemicals.

More than three million cycles in the test

For easy installation and maintenance of the new sliding step, the design emphasised adjustment-free solutions. All pre-settings are made at the factory, and later component replacement requires no adjustment. This also reduces complexity in production. The high helix lead screw and high helix lead screw nut can be easily replaced on site by the customer and installed easily. The igus® solution also has good durability. A belt drive tear could mean train failure. But the worst thing that can happen with an igus® lead screw nut is increasing clearance, a slow process that can be detected well in advance and corrected in good time. For gap bridging, two test series were performed at the Austria location. One was a worst-case test in which the step runs against an obstacle – usually the platform. We ran a million cycles simulating such an error and saw no failures. In normal operation, everything worked flawlessly after 3.5 million test cycles.

System in plan for arctic temperatures

The two sliding steps with the two lead screw lengths are used primarily in temperate climate zones. They are designed for temperatures down to -25°C. Systems for temperature ranges down to -40°C are currently in the planning phase. The igus® laboratory is already running test series for material developments for permanently low temperature ranges in order to provide an optimal quality solution. A train has a service life of at least 40 years. Individual coaches can be used for up to 60 years. The first main maintenance with replacement of components usually happens after 15 years. Safety checks are made every three months. The sliding step itself is cleaned only twice a year. These figures illustrate how robust, reliable, and durable the components must be. They have to work not only in the lab, but above all, in the field.

Products used

Maintenance-free in rail transport

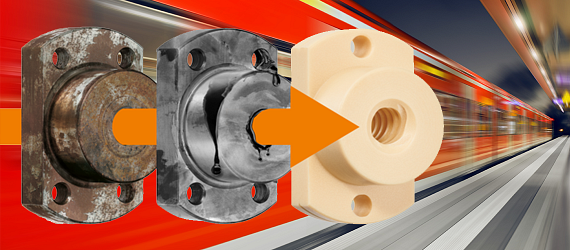

How can the wear on sliding doors in trains be reduced by 25%? And can maintenance costs be prevented in gap bridging? dryspin® lead screw technology offers the perfect alternative to conventional metal lead screw nuts for railway technology. It is completely lubrication- and maintenance-free and therefore ideally suited for 24/7 operation.Leadscrews in railway technology