Dosing linear robot - DUS architects

What was needed:

3D printer XXL

Requirements:

corrosion resistance, despite being installed in a container, the function of the room linear robot must be guaranteed (self-aligning & parallelism error)

Material:

igus room linear robot

Industry:

construction industry/3D printing

Success for the customer:

individual robot system which enables oversized 3D printing components

3D printer XXL

Requirements:

corrosion resistance, despite being installed in a container, the function of the room linear robot must be guaranteed (self-aligning & parallelism error)

Material:

igus room linear robot

Industry:

construction industry/3D printing

Success for the customer:

individual robot system which enables oversized 3D printing components

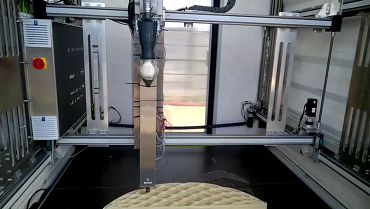

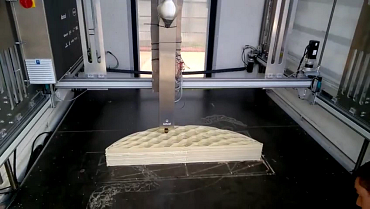

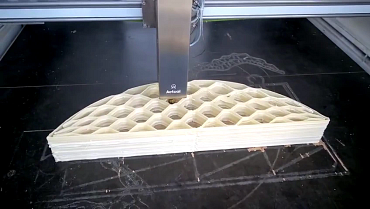

Go to application

The idea behind the application is to reuse recycled plastic in the construction industry. Elements for building houses are created in an XXL 3D printer, which was integrated in a sea freight container. Due to its transportability, the system is extremely flexible and can be used directly on site without the need for complex transport of components.The problem

Components for building houses are often very large, which is why a large 3D printer has to be used. With dimensions of 3m x 3m x 6m, this printing unit is far above the usual size.Depending on the area of application, humidity and dirt play a major role. The room linear robot therefore had to be free of lubrication and maintenance to ensure smooth operation.

The solution

An igus room linear robot XXL in combination with a 3D printing head. At the back, the plastic waste is loaded in a prepared form, while at the front the printer prints components which then are ready to be delivered for the building process. The unit can be transported completely in a freight container from place of use to place of use.Low Cost Automation shop

Cost-effective robotics for your automation project

You can find the right robot for your individual application in our online shop.Browse, get information and order easily.

To the shop