Intelligent condition monitoring for machines and equipment - i.Sense

"Trust is good, control is better" ... made easy with i.Sense from igus® - smart plastics

If smart plastics are used for condition monitoring, they immediately report any unexpected operating states, switch off the system, or emit an alarm. Industrial manufacturers use this function to minimise system failures, downtime, and maintenance costs. Do you want to use machines, components, and resources effectively with all the available digital advantages? Would you like to use smart plastics to pursue a practical, cost-effective method of promoting digitalisation in maintenance?Download smart plastics brochure

Always have an eye on everything in the crane industry

Success stories with i.Sense from smart plastics

Heavy loads, long periods of use, and a wide variety of weatherconditions – all reasons why cranes must fulfil very stringent performance requirements. Ensuring that they do so at all times requires reliable condition monitoring concepts such as our i.Sense with smart plastics.Intelligent condition monitoring on cranes

smart plastics FAQs

Condition monitoring with igus®: definition, differences, advantages and disadvantages, and many more explanations

What is condition monitoring?

In industry, condition monitoring refers to the regular to continuous recording or monitoring of the condition of machinery, equipment, components, or processes.

In industry, condition monitoring refers to the regular to continuous recording or monitoring of the condition of machinery, equipment, components, or processes.

What conditions can be monitored with these condition monitoring systems?

Various condition monitoring systems can be used to record an extremely wide range of physical machine parameters, from acceleration to motor vibration to tensile forces.

Various condition monitoring systems can be used to record an extremely wide range of physical machine parameters, from acceleration to motor vibration to tensile forces.

What is the purpose of continuous condition monitoring?

It optimises maintenance and servicing schedules, stabilises processes, and increases personnel safety. Machine data is converted into actionable insights that deliver real operational benefits and financial returns.

It optimises maintenance and servicing schedules, stabilises processes, and increases personnel safety. Machine data is converted into actionable insights that deliver real operational benefits and financial returns.

3D CAD portal for smart plastics

Design intelligent energy chain systems faster. CAD models for all smart components.

Our intelligent e-chain systems are already reliably in use in hundreds of thousands of applications worldwide - from beverage machines and CNC machines to steel mills. Unsupported lengths can be bridged without problems and long travels are conceivable for the most varied of industries.To the 3D CAD portal

For this and many other issues, such as the use of condition monitoring systems in the smart factory, overall equipment effectiveness (OEE), and the Internet of Things, and for all the answers to the most frequently asked questions from our customers, see our igus blog:

360° insight into the igus test laboratory

Call up all smart plastics test rigs via the main menu and area E08.Integration

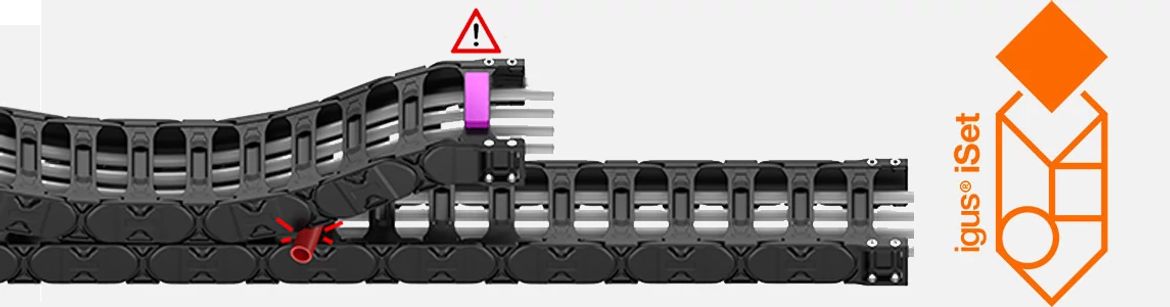

If there is an existing or imminent fault, the sensors inform the system and recommend a shutdown. Operation requires no additional external data-processing modules.But i.Sense for predictive maintenance can be integrated at any time.

_370.jpg)