Permanent connection - Tried and tested: Insulation displacement connection technology (IDC) in movable cable systems from igus® & HARTING

Profile

- What was needed: Testing and resilient test statements of dynamic cable systems with insulation displacement connections (IDC) according to the relevant standard EN 60352-3

- Requirements: Dependability and long service life of the plug connection, constant vibrations and several thousand bending and movement processes

- Product: chainflex CFBUS cables & HARTING RJ Industrial 10G connectors

- Field of application: Industrial automation

- Success for the customer: Assurance that CF cables in conjunction with insulation displacement contact technology meet the highest reliability requirements (although not mentioned in EN 60352-3)

About insulation displacement contact technology: It may initially come as a surprise that insulation displacement contact technology (IDC technology) is also gaining acceptance in industry in view of the high demands. Here the insulated conductor is pressed into a gap which tapers and whose flanks are designed as cutting edges. The cutting edges cut through the insulation and then touch the actual conductor, which is deformed during this process. Thus - if the process has been carried out correctly - a long-term stable cold weld and a gas-tight, i.e. non-aging connection is produced. Originally developed for office communication and IT network technology, this technology enables a simple, time-saving and solderless connection without special tools. And it is precisely these advantages that the industry would like to exploit.

The challenge

In view of the fact that hundreds or thousands of these cables and connections are used in larger systems, extremely high demands must be placed on each individual core and each individual connector in terms of service life and dependability. This requirement is not so easy to meet only because the cables are exposed to high mechanical, climatic and chemical stresses, depending on the application. This applies in particular to applications in which the cables travel along moving system components such as linear and handling axes or robot arms.What applies to the cables also applies to the plug connections. Even constant vibrations or several thousand work cycles per shift with a corresponding number of bending and movement processes of the cables must not cause the individual cores to come loose from the clamp. This requirement can be easily formulated and written down. However, in practice their compliance requires great care in the selection of the connection technology and great care in the connection of cable and connector.

There is a standard for such connections: EN 60352 "Solderless electrical connections" in part 3 contains specific regulations for the product area "Solderless accessible insulation displacement connections" and mentions "General requirements, test methods and instructions for use". This standard refers to cables whose cores consist of one wire or are composed of seven wires. In the industry, however, cables with 19 wires are often used, which are needed to ensure the dynamics required for moving cables. This means that the Ethernet and Profibus cable cores with 19 wires, which are connected to their connectors via insulation displacement connectors, do not correspond to the stipulations of the standard.Also the connector approval is not given under these conditions.

Solution

Since the Ethernet and Profibus cable cores with 19 wires connected to their connectors via insulation displacement connectors do not comply with the standard, igus and HARTING took the logical step of testing the cable systems that have been successful in practice according to the requirements of EN 60352-3. The accredited HARTING test laboratory in Espelkamp could be used for this purpose, as well as the comprehensive test facilities in the igus test field.The scope of testing included long-term trials with harnessed cable systems, which were stressed according to defined requirement profiles. The possibility of processing in the connector and the contacting of stranded wire to insulation displacement termination was tested. Even adverse environmental conditions such as frequent temperature changes and humidity were simulated. The aim of the tests was to apply the test procedures specified in EN 60352-3 and to expose both the cables and the insulation displacement connections to the highest stresses.

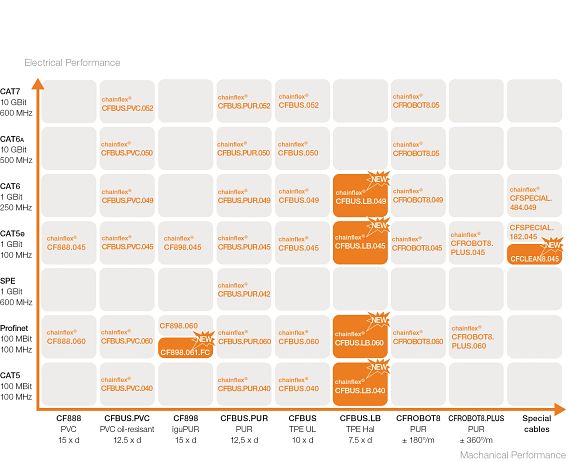

In conclusion, the tests were carried out to the complete satisfaction of HARTING and igus.The micrographs showed a flawless cold welded joint even after intensive dynamic use, which suggests a long service life can be expected even if the tests are continued. The tests described were carried out on the standard bus cables of the chainflex range. For Ethernet systems these are the CFBUS.04x series, for Profinet the CFBUS.060 series. Also included were cables with jackets made of PVC (for use in the wood industry), PUR (for applications where oil resistance is required), halogen-free TPE and cables with UL approvals. The cables for robotics applications CFROBOT8.045 (Ethernet) and CFROBOT8.060 (Profinet), which are particularly resistant to dynamic loads, were also successfully tested.

chainflex® Ethernet cables