Technical data:

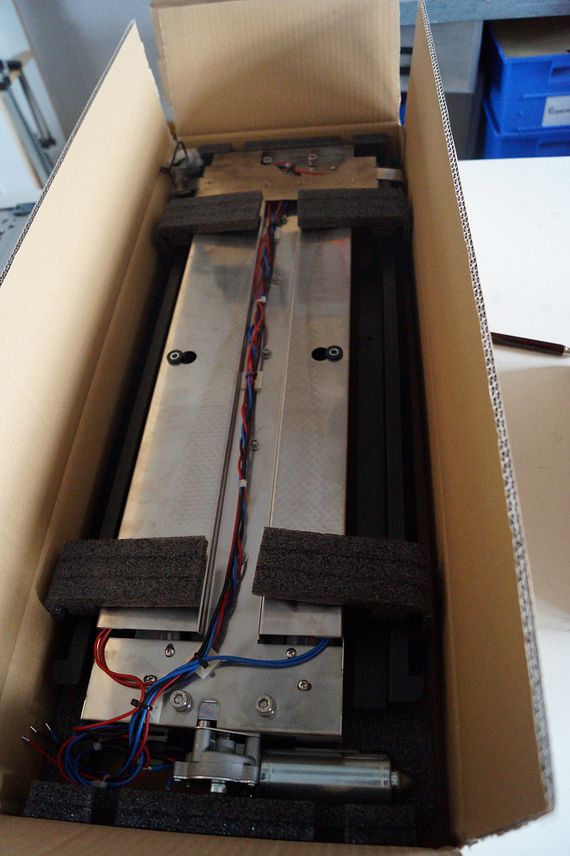

- What was needed: A maintenance-free, vibration-resistant, durable motorized TV lift

- Requirements: Very limited installation space, no vibrations with a stroke of 500 millimetres (despite the 32-inch screen's weight of around 7.5kg), long service life, no maintenance, silent operation, vibration-resistant, easy installation

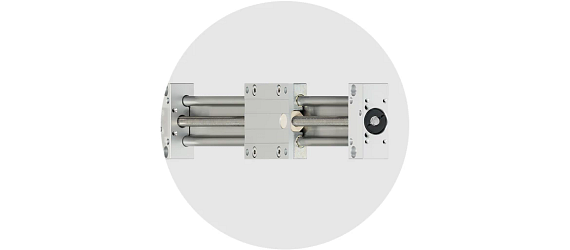

- Products used: drylin W1040 guide with matching dryspin lead screw

- Success for the customer: Ten times the required strokes, best price-performance ratio, easy assembly thanks to single or double rails, best friction and wear results thanks to hard anodised aluminium, extremely insensitive to dirt because lubrication is eliminated, suitable for applications in clean and hygienic environments

Make a contact request

Zero complaint rate: Aluminium guide withstands more than 100,000 strokes

igus linear guides guarantee high quality standards in caravan construction and withstand harsh conditions

The request from FAWO, Europe's largest caravan interior fittings distributor, was a demanding one: the experts at CERES Entwicklungs & Produktions GmbH were to produce a maintenance-free, vibration-resistant, durable motorised TV lift. Many years of development expertise and high-quality construction elements brought about the desired result. Now 500 of these vehicle components are produced every year, with igus linear guides playing a leading role.

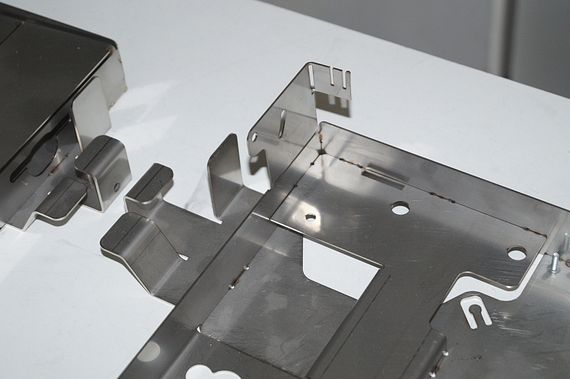

CERES Entwicklungs & Produktions GmbH in Ottensoos near Nuremberg, Germany was founded in 2012. Founder and managing director Werner Schuss considers his company an interface between design and production: "The key to results that can be amazing is to create synergies between different areas. The affinity for design and the experience of what is feasible from a manufacturing perspective adds value for our customers." And customers come from medical technology, optics, precision engineering and electromechanics, plastics technology, IT, and the automotive sector. In addition to well-known industrial customers such as Zeiss, Bosch, Hilti, IST Metz, and Siemens, medium-sized and small companies are clients. Says Schuss, "We develop our own products with distribution partners such as Hörmann, ISONO, and FAWO. Depending on the requirements, we produce initial functional samples from one to 1,000 pieces in a very short time. We support product development from the initial idea to series production."

FAWO, the European leader in caravan interiors, was also the company that commissioned a motorised TV lift for such interiors. This lift has special requirements for its guide: One is the very limited installation space behind the corner bench backrest. Another is eliminating vibrations when the 32-inch screen is extended as much as 500 millimetres - since it weighs around 7.5 kilograms. Other constraints from the specifications: service life of at least 10,000 strokes, maintenance-free, noiseless operation, vibration-resistant, simple installation.

Supporting purchase decision: "Good from experience"

Given all this, Managing Director Werner Schuss found the guide system decision easy: "I know igus very well and have known it since the 1980s. In the past, plain bushings and energy chains have been used in various designs and

FAWO, the European leader in caravan interiors, was also the company that commissioned a motorised TV lift for such interiors. This lift has special requirements for its guide: One is the very limited installation space behind the corner bench backrest. Another is eliminating vibrations when the 32-inch screen is extended as much as 500 millimetres - since it weighs around 7.5 kilograms. Other constraints from the specifications: service life of at least 10,000 strokes, maintenance-free, noiseless operation, vibration-resistant, simple installation.

Supporting purchase decision: "Good from experience"

Given all this, Managing Director Werner Schuss found the guide system decision easy: "I know igus very well and have known it since the 1980s. In the past, plain bushings and energy chains have been used in various designs and

devices used. We were certain that the drylin guide system would ensure we had no stress from the TV lift." The drylin W1040 guide with the matching lead screw achieves ten times the required strokes - CERES stopped the tests after 100,000.

drylin W profile guides are a pre-assembled, highly flexible, cost-effective system. According to Werner Schuss, the price-performance ratio played an especially important role: "The 'Caravan' segment is extremely price-sensitive, and there is huge competition. Alternative guide systems were much more expensive, and were heavy and complex to handle." André Hock, the igus Technical Sales Consultant who supported the project, adds, "Single or double rails make installation very easy. Hard-anodised aluminium is used for the rail material and provides the best friction and wear results." Moreover,

the absence of lubrication makes the profile guide system extremely insensitive to dirt, and its cleanliness also makes it suitable for applications in clean and hygienic environments. drylin W is also available in stainless steel for special applications or with manually adjustable bearing clearance.

Perfectly matched

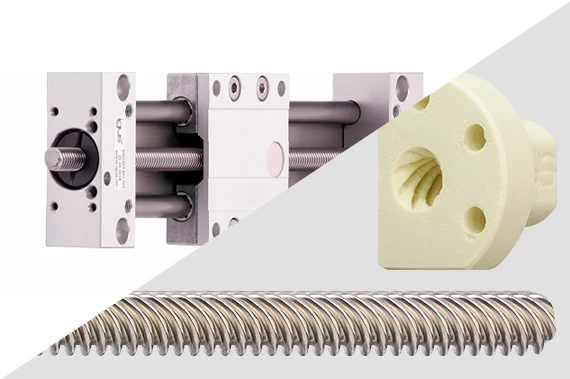

The design engineers at CERES also added a lead screw from the dryspin product range to the guide. It is based on wear-resistant, high-performance igus polymers specially developed for lead screw drives. The lead screws ensure efficiency and long service life. Their efficiency is as high as 82 percent. In CERES's case, the pitch is 25 millimetres so that TV retraction and extension as fast as possible. It now takes only 15 to 17 seconds. An electronic control unit developed at CERES supplies the hoist motor with 12 V DC. EMC and mechanical safety issues are taken into account.

Perfectly matched

The design engineers at CERES also added a lead screw from the dryspin product range to the guide. It is based on wear-resistant, high-performance igus polymers specially developed for lead screw drives. The lead screws ensure efficiency and long service life. Their efficiency is as high as 82 percent. In CERES's case, the pitch is 25 millimetres so that TV retraction and extension as fast as possible. It now takes only 15 to 17 seconds. An electronic control unit developed at CERES supplies the hoist motor with 12 V DC. EMC and mechanical safety issues are taken into account.

Rounded tooth flank geometry reduces movement of the contact area between the lead screw nut and lead screw. This allows dryspin lead screw nuts move almost silently and without vibration. The larger distances between the individual thread pitches mean that the thread ideally matches the properties of the lubrication-free high performance polymers.

Another technical detail: The proportion of tribologically optimised polymer in the thread pitches can be increased by a factor of 1.3 for all sizes. More wear-resistant material and higher efficiency are crucial for up to five times the service life of standard geometries. The larger the lead screw diameter, the greater the impact of this feature. For CERES, the diameter is ten millimetres.

Facts, facts, facts

One source of the corresponding values is the extensive tests in the igus test laboratory in Cologne. igus' André Hock explains: "Several hundred tests are set up and carried out on thread test rigs every year. The results are incorporated into various online tools. which are freely available on the igus website and used to determine the service life and required torque."

For CERES Managing Director Schuss, the experience gained from applications that have already been implemented was also important: "The guides are used in a reclining seat for aircraft, for example. And after reviewing a working sample, the decision was clear." Especially since the currently dimensioned igus components provide five times the required safety for the TV lift.

Another application is being planned - a rear view camera which also requires quick guidance for extending and retracting is under discussion.

Another technical detail: The proportion of tribologically optimised polymer in the thread pitches can be increased by a factor of 1.3 for all sizes. More wear-resistant material and higher efficiency are crucial for up to five times the service life of standard geometries. The larger the lead screw diameter, the greater the impact of this feature. For CERES, the diameter is ten millimetres.

Facts, facts, facts

One source of the corresponding values is the extensive tests in the igus test laboratory in Cologne. igus' André Hock explains: "Several hundred tests are set up and carried out on thread test rigs every year. The results are incorporated into various online tools. which are freely available on the igus website and used to determine the service life and required torque."

For CERES Managing Director Schuss, the experience gained from applications that have already been implemented was also important: "The guides are used in a reclining seat for aircraft, for example. And after reviewing a working sample, the decision was clear." Especially since the currently dimensioned igus components provide five times the required safety for the TV lift.

Another application is being planned - a rear view camera which also requires quick guidance for extending and retracting is under discussion.

Do you have questions about drylin® lead screw technology?

Our expert Thorben Hendricks will answer all your questions about drylin lead screw technology. Just fill out the contact form, and we will take care of your issue. We are looking forward to your message!► Request contact online

► Make an appointment

► Expert support upon request by phone or with the video chat function

► Order a free sample

Request expert support here

dryspin® lead screw drives in vehicles

Five reasons why dryspin® technology is used in automobiles

With the dryspin lead screw technology, it is easy to design individual lead screw nuts and lead screws exactly according to the wishes of the customer. Our experts will be happy to help you choose the right lead screw drive and will ensure that deliver times are short. The wide choice of materials and complete absence of a need for lubrication or maintenance mean that the lead screw drives can be used in almost any area of the automotive industry. They are ideal for small installation spaces and operate almost silently even when the drive torque is low. Uncomplicated integration into your vehicle or assembly is also an aspect that speaks in favour of the cost-effective alternative to conventional lead screw drives made of metal.