Brewery machinery with igus® motion plastics

- Malting

- Milling

- Mashing

- Boiling

- Fermenting

- Filtering

- Packaging to name a few.

Would you like more information about the range of products suitable for Brewery machines? Our experts will be happy to get in touch with you.

Selected motion plastics ideal for brewery machinery

Spherical insert bearings

- Resistant to edge pressures

- Lubrication-free, corrosion-free, resistant to dirt

- Low moisture absorption

- Find out more

3D printed grippers

- 50 x more wear-resistant than standard plastic

- iglidur® materials are stable and long lasting

- Can be printed very quickly!

- Find out more

Tribo Coating

- Offers protection against wear

- Reduces noise

- Offers excellent wear & sliding properties

- Find out more

Tribo tape

- Reduces noise

- Creates smooth sliding surface

- Adhesive and non adhesive backed are available.

- Find out more

Stainless steel guide roller

.jpg?crop=no&color=ffffff00&w=370&quality=80)

- Ideal for excessive temperaures

- Food Approved materials

- Resistant to a range of chemicals

- Find out more

Back to all industries

- For more information on all the industries that uses igus® products such as:

- Aerospace

- Cleanroom

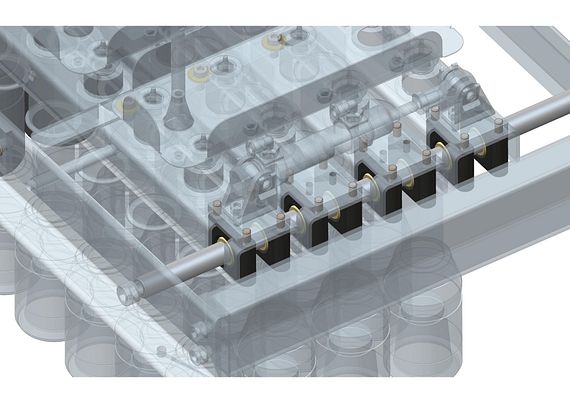

Application examples of igus® in brewery machines

DIY beer dispensers!

Helping keep bottles moving safely

The ESTM pillow block bearings are completely made from iglidur® polymer materials and have a range of different spherical ball materials to suit all applications.

iglidur® plain bearings work in breweries at extreme temperatures

Frequently asked questions about igus® products in brewery machinery

How to save time and money with bearings?

igus® products do not require lubrication meaning cost saved and also time in maintanance. igus® offers a service life calculator for most products so knowing the life time helps with arranged downtime as opposed to unexpected downtime.

Can I test a bearing?

Of course, we have sample boxes and also can offer individual specific samples that you can test.

How do I know the bearing will work?

This one is easy. We test. We have the largest test laboratory in Europe and do continuous testing. We have real life applications that we test too. This has allowed us to be able to offer the life time calculators.

How big is the brewing industry?

The brewery industry is huge and in the UK we have a large range of breweries such as Heineken, Carlsburg and Marstons

What type of industry is brewing?

The brewing industry is a global multinational business which produces beer. This can be as a microbrewery, depending on the size of the establishment.

How much does it cost to make a pint of beer?

How much does it cost to make a pint of beer? This question is complex and has many elements to consider such as machines in production to delivery. igus® has been helping breweries become more economically friendly and saving them time and money at the same time. Find out how....

In the UK we are massive beer drinkers! Maybe not something we should be proud of; however, the facts are what they are, we like a pint of beer. Unsurprisingly, we therefore have a huge number of breweries in the UK, some are small and some are well known brand names, but brewing beer is a massive market in the UK....

%20(3).jpg?crop=no&color=ffffff00&w=370&quality=80)