Technical data:

- What was needed: A biscuit moulding machine capable of producing the wide variety of shapes required by the customer and the market

- Requirements: 100% lubrication-free and maintenance-free, resistant to flour dust and regular hot water washing, precision

- Products used: dryspin® lead screw, drylin® W single rail WS, drylin® W pillow block

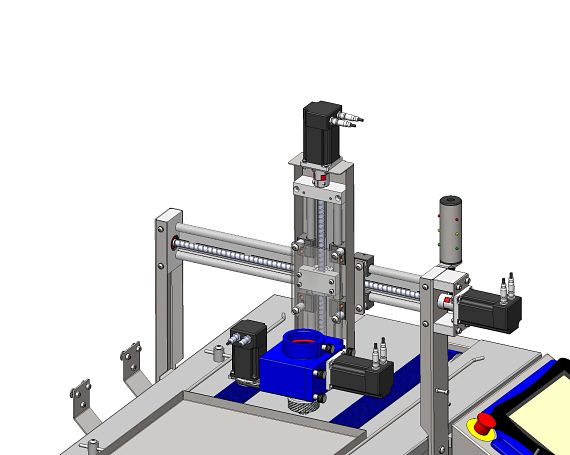

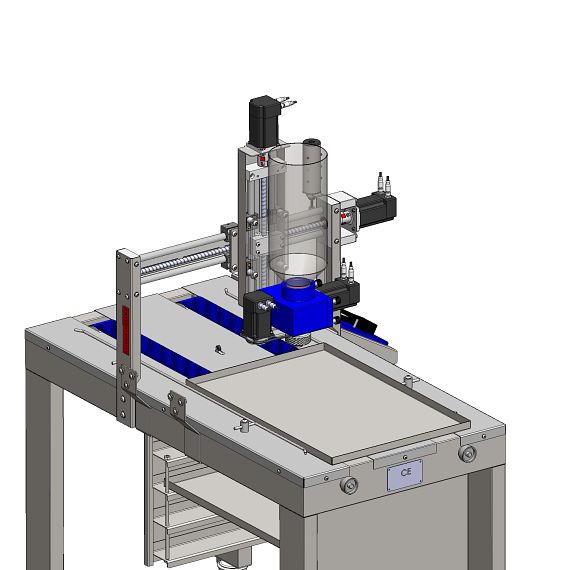

- Success for the customer: The machine, equipped with a pump installed on electric axes, performs designs of biscuits or decorations on cakes with flush pouring of dough. The axes are driven by four stepper motors, and transverse and vertical displacement is on the drylin® guide rail with built-in dryspin® lead screw. The guides are equipped with four WJ200UM pillow blocks.

Do you need more information? Contact us here

Problem

CARTESIA is a robot and computer-controlled moulding machine, which unlike the standard casting machines already introduced and established in the market, is able to produce the most varied shapes required by the customer and the market. Conventional moulding machines for biscuits are rather limited in movement and creating shapes. Due to food contact and environmental requirements, for e.g. flour dust and temperature fluctuations, all installed parts must be carefully selected. Alternative guide solutions were out of the question due to regular lubrication and maintenance. In addition, all installed parts should be cost-effective.Solution

It operates with a single nozzle equipped with a quick coupling, which facilitates format changeover, which can be performed in a very short time, estimated at a maximum of 30 seconds. CARTESIA's quick coupling and adapters allow the use of existing spouts or spouts made with commercially available 3D printers. CARTESIA, thanks to its internal PC and CNC control system, works with different axes that allow to move the spout in all directions, creating any design without shape and size constraints. The igus® solutions offer 100% freedom from lubrication and maintenance and no adherence of flour dust.Further application pictures:

Do you have questions about drylin® lead screw technology?

Our expert, Thorben Hendricks, will answer all your questions about dryspin lead screw technology. Just fill out the contact form, and we will address your concerns. We are looking forward to your message!► Request contact online

► Make an appointment

► Expert support upon request by phone or with the video chat function

► Order a free sample

Request expert support here