3D printer parts - How to make a 3D printer from igus® parts

3D printer parts need to be long lasting and fit your exact measurements. Are you currently building your very own 3D printer? Luckily at igus® we can provide you with all the necessary parts to get your printer moving lubrication free! See our entire list of relevant products below

Lubrication-free and maintenance-free technologies and components from igus are already playing a central role in most assembly kits and blueprints for 3D printers. Tribologically optimised high-performance polymers ensure enhanced 3D printing technology and lower costs.

Would you like more information about igus® parts in 3D printers or advice on making a 3D printer? Our experts will be happy to get in touch with you.

Lubrication-free and maintenance-free technologies and components from igus are already playing a central role in most assembly kits and blueprints for 3D printers. Tribologically optimised high-performance polymers ensure enhanced 3D printing technology and lower costs.

Would you like more information about igus® parts in 3D printers or advice on making a 3D printer? Our experts will be happy to get in touch with you.

Contact our expert

3D printer parts with igus®

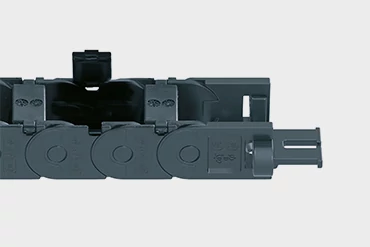

E2 micro energy chain

- High torsion resistance

- Smallest inner heights and bending radii

- Large pins for long service life

Visit the shop

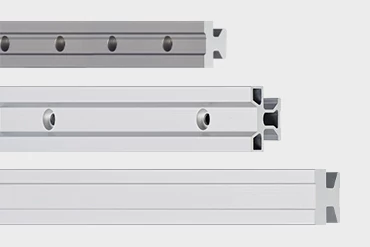

drylin® W guides and rails

- Corrosion-resistant, wear-resistant and hygienic

- Resistant to dirt, dust and humidity

- Quiet operation

Visit the shop

drylin® E stepper motor

- Powerful in five sizes

- Motors with metric connector or standard wires

- With encoder and brake for extra safety

Visit the shop

drylin® trapezoidial lead screw

- Anti-backlash function available

- FDA approved available

- Maintenance-free dry operation

Visit the shop

drylin® W pillow block bearings

- Fast bearing change without dissasembly

- Smart maintenance directly on the rail

- Roller bearing

Visit the shop

iglidur® i180-PF filament

- Good combination of high wear resistance

- Good processing ability with an enclosed printer and igus® adhesive film.

Visit the shop

dryspin® high helix lead screw

- High helix, trapezoidal and metric threads

- Stainless steel, steel or hard anodised aluminium

- Up to 30% longer service life

Visit the shop

Do you need 3D printed parts custom printed?

Do you require individual, wear-resistant components for building your 3D printer or are looking for solutions for quickly manufacturing abrasion-resistant prototypes or small volumes?Then you can use the igus® 3D printing service: simply upload CAD, select material and compare prices right away. The completed parts are ready to ship in one to three days. We also offer 3D printing materials for food contact, ESD protection, fire safety and further special properties.

Click here

Application examples of igus® 3D printer parts

Extreme precision and performance: XXL 3D printer

3D printing and house construction? Do they have anything to do with each other? The example of the Dutch "Europe Building" in the Amsterdam Marine Quarter shows that it works. Our drylin e-linear robots and engineering expertise made this possible.

Learn more about this application

Quick assembly, cost-effective price, high quality

The 3D printer from Cobot impresses not only with its large installation space but also with its innovative design. The few installed parts are fail-safe and give the machine a modular and quickly assembled design. Our drylin linear technology enables completely lubrication-free and maintenance-free operation.

Learn more about this application

Ready-to-install system solution in 3D printers from EVO tech

Where there is little installation space, space-saving products and cables with tight bend radii are in demand. A completely ready-to-install complete solution consisting of energy chain, cables, drylin linear bearings and motor unit fits into the compact design of this 3D printer from EVO tech GmbH.

Learn more about this application

Cost-effective serial printer with high running performance

High running performance, lubrication-free and robust: these are the requirements for linear components in 3D printers. Even in the first serial printer from Kiel-based company Kühling&Kühling, the drylin linear bearings used must withstand high accelerations and temperatures of up to 80°C.

Learn more about this application

High-performance 3D printer with drylin low profile guides

This 3D printer allows rapid creation of plastic prototypes. The printer is characterised by a high degree of flexibility, which is achieved, among other things, by a print head for two filaments and linear guides with flexible magnetic joints. For fast, low-noise and precise movements, the developers relied on our drylin linear guides and carriages.

Learn more about this application

3D printer for metal parts: precision at 150°C and dust

This laser-based 3D printing machine creates custom metal parts from titanium, aluminium, steel, or even gold. The printing process requires maximum precision when applying metal powder layers at high temperatures. For this reason, the manufacturer relies on a drylin linear guide system.

Learn more about this application

Compact and cost-effective 3D resin printer

The central element of a 3D DLP resin printer is the Z axis motion system. A solution was sought here that guarantees high accuracy and is cost-effective.

Our iglidur bearings and drylin linear guides ensure, among other things, smooth movement of the pressure carriage and a minimum print resolution of 37.5 micrometres.

Our iglidur bearings and drylin linear guides ensure, among other things, smooth movement of the pressure carriage and a minimum print resolution of 37.5 micrometres.

Learn more about this application